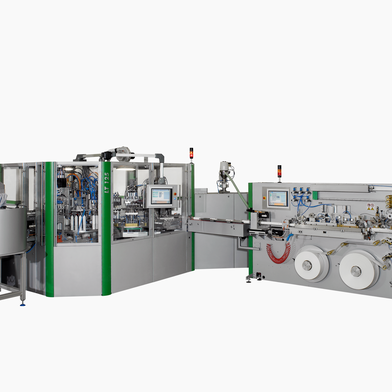

Making tube production simple, compact and cost effective

The Technology

The Mini 120 comprises a compact seamer, header and capper, with the option to also do top seal. This really is the cost effective solution for producing small diameter tubes.

Both the splicing table and accumulator come as standard for the seamer. Resistive heating or HF seaming process means it can handle a wide range of laminates up to 300 μm and aluminum barrier up to 20 μm.

The seamer is integrated with the Mini 120 HC to complete the process of heading, optional top seal and capping. Furthermore, the tubes can be packed by adding the MiniMaster packer.

Your Benefits

- Most compact machine on the market

- One-step operation of shoulder molding

- Reliable processing of nozzle and special shaped caps

- Optimized cost per output

- High efficiency

- Compact design

Only 15 m2 are needed to be able to produce 120 smaller tubes per minute - including the top seal and capping process.

Mini 120 Video

Mini 120 Technical Data

| Tube diameter | 12.7 - 23.1 mm |

|---|---|

| Tube length | 40 - 140 mm |

| Speed | 120 tpm |

Oval Capability

for the production of oval tubes with small diameters

With the oval capability, you can meet the growing demand for oval tubes with small diameters.

Additional functions with oval capability

- Improved cooling system: For thick and thin recyclable PBL laminates in both the seamer and heading area.

- Body orientation unit: Developed and installed in the new generation of the Mini 120 Line.

- Servo compression and servo unloading: For more precise and efficient production processes.

- New cap system: Specially developed for oval screw caps.

- Shoulder designs and cap types

The Mini 120 Line oval capability supports various shoulder designs and cap types, including screw caps, conical caps, stand up and nozzle caps. These designs can be customized to your specific requirements. Our team is ready to support you in the development of customized shoulder designs.