Become a supplier of Brückner Maschinenbau

We are looking forward to working with you

Please select the product group you want to apply to and fill out the application form. You are welcome to add further information about your company to your message. Your application will be checked and answered promptly.

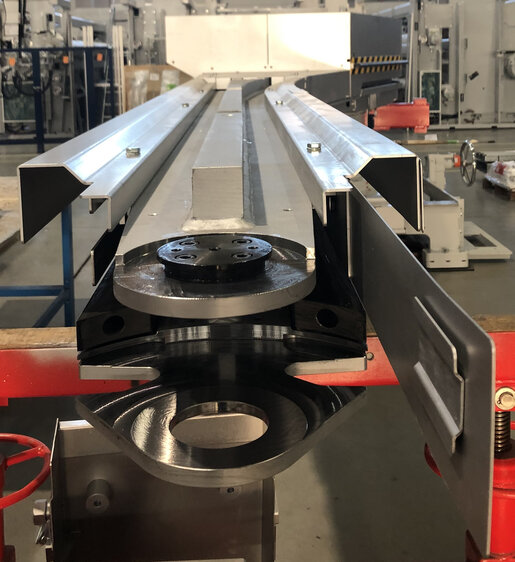

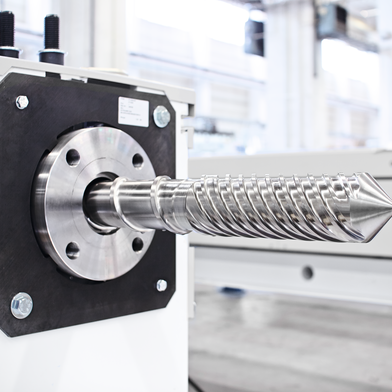

Extrusion components

The extrusion process forms an essential component of Brückner lines; here, the plastic granules are processed into a high-quality melt. The extrusion plant usually consists of a main extruder and several co-extruders. In order to meet the technical requirements involved in this process, top surface qualities and precise execution within the required tolerances are necessary. The output rate varies from a few hundred kilograms up to ten tonnes per hour. An extrusion system consists of the following components:

Portfolio

- Extruder

- Single screw extruder

- Twin screw extruder (Co-rotating)

- Melt pumps and drain valves

- Melt filters:

- Large area filter with candles / discs

- Back flush filter

- Melt Pipes

- Complete systems including heating and insulation

- Melt carrying components according to drawing

- Melt dies and adapters

- Flat dies (often in several layers) with working width 1.000 to 3.500

- Turn around adapter and feed blocks for combining several melt streams

To apply as a supplier, please click on the button below and fill in the following application form.

Complete machines & system-assembly groups

This range of parts is normally purchased as a complete unit including engineering. The suppliers are usually heavily involved in the process technology and take overall responsibility for these systems from design to process guarantees.

Portfolio:

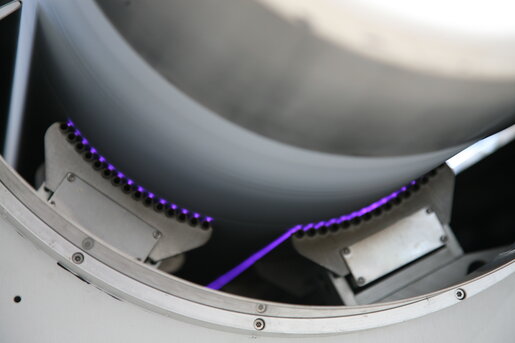

- Surface treatment of the film for working widths of up to 11m and speeds of up to 650mpm

- Corona

- Flame treatment

- Inline-Coating (working width 1 to 3 m)

- Web cleaning

- Antistatic units: Charging and discharging units

- Film measurement for working widths of up to 11m and speeds of up to 650mpm

- Inline - Thickness measurement of cast film or end film

- Inspection systems

Automatic optical inspection systems (AOI) for monitoring film quality

- Drying, conveying and dosing of plastic granulates

- Degassing systems for twin screw extruders

- Vacuum pumps

- Separator and condensation container

- Shredding and conveying of film waste

- Heating / cooling units for the heat transfer medium thermal oil or water

To apply as a supplier, please click on the button below and fill in the following application form.

Engineering parts for medium & small series

For our chain systems for stretching the film, we require contract manufacturing parts which are produced in quantities of between 2,000 and 100,000 units per year. In order to guarantee the consistently high quality of these serial parts, they are subjected to a strict first-sample process under serial production conditions. During this qualification process, process capability is also ensured. Subsequent changes to the manufacturing process are only permitted after express approval by Brückner.

Portfolio:

- Casting parts: Investment casting and shell mould casting (unit weight up to 6 kg)

- Forged parts and fine blanking parts

- Machining of castings and forgings

including surface treatment (e.g. nickel plating)

- Turned parts (max. diameter 30mm) made of steel including

- Grinding / hard turning

- Heat treatment (e.g. Nitriding, hardening)

- Surface treatment (e.g. Nickel plating, oil burnishing)

- Milled parts made of steel

Including surface treatment (Nickel plating, oil burnishing)

To apply as a supplier, please click on the button below and fill in the following application form.

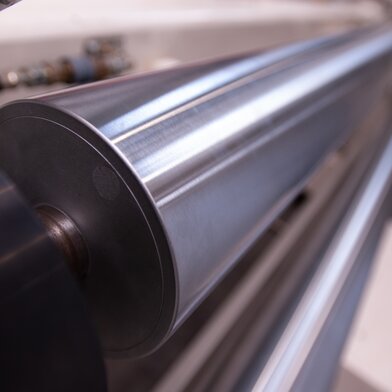

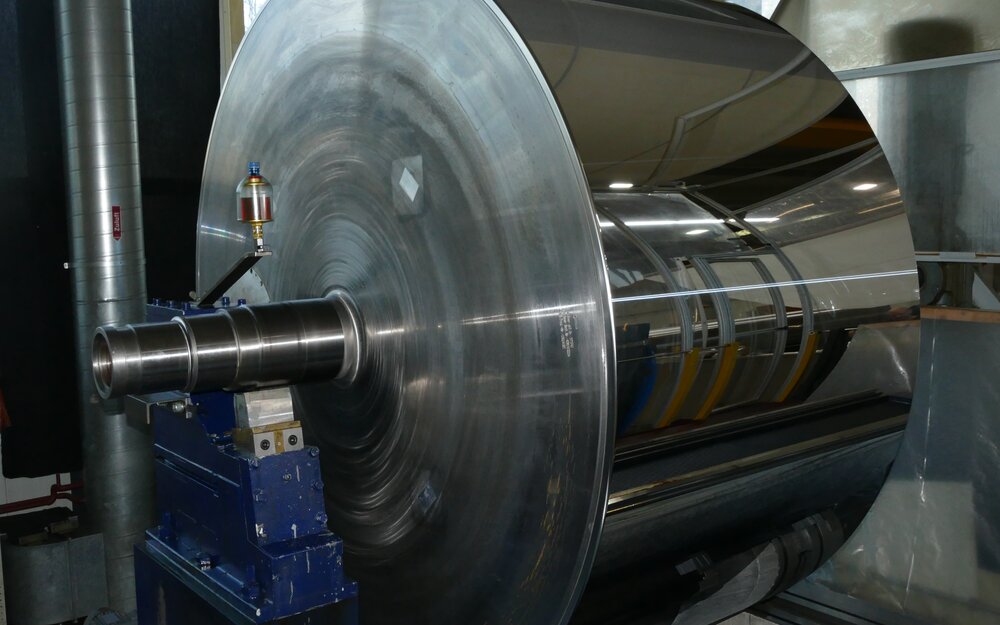

Rollers

Portfolio:

- Guide rolls

- Diameter 120 – 400 mm

- Cylinder length 800 – 3500 mm

- Basic body materials: steel, stainless steel, aluminum

- Surfaces: spray coating, anodizing, rubber, ceramics, grinded stainless steel

- Heating and cooling rollers

- Double shell rollers

- Diameter 150 – 800 mm

- Cylinder length 800 – 11.000 mm

- Chill rolls

- Double shell rollers

- Diameter 800 – 3.600 mm

- Cylinder length 800 – 3.400 mm

- Rubberized rolls

- Diameter 120 – 720 mm

- Cylinder length 800 – 11.000 mm

- Basic body materials: steel, stainless steel, aluminum, carbon fiber

- Carbon fiber-rolls

- Diameter 280 – 670 mm

- Cylinder length 5000 – 11.000 mm

- Surfaces

- Chrome

- Nickel

- Spray coating e.g. tungsten carbide

- Ceramics e.g. chromium oxide

- Rubber e.g. EPDM, HNBR, silicone

- Special rollers

- Spreader rolls, vacuum rolls, etc.

- Winding core

- Flame treatment roller

To apply as a supplier, please click on the button below and fill in the following application form.

Electrical components

In order to achieve high production speed and to enable high-quality film, we require reliable and efficient drive technology, powerful electronics and intelligent control technology. As digitalization continues to develop, we experience an increasing need for sensors in our stretching lines. We are looking for reliable suppliers who can deliver high quality products. We are also looking for partners who will work with us to further develop products and offer Brückner access to the latest innovative solutions on the procurement market.

Portfolio:

- Drive technology

- Torque, asynchronous, gear and linear motor

- Torque, asynchronous, gear and linear motor

- Automation technology

- Inverters, controls

- Electrotechnical assembly production

- Cables & wires

- Sensors

- Switchgear

- Cabinet

To apply as a supplier, please click on the button below and fill in the following application form.

Purchased parts

A wide range of purchased parts are installed in a film stretching system. We are looking for reliable suppliers who can supply us with high-quality products. We are also looking for partners who will work with us to further develop products and offer Brückner access to the latest innovative solutions on the procurement market.

Portfolio:

- Hydraulic pneumatics

- Drive components

- Transmissions, drive shafts, belt + slices, brakes, screw Jacks

- Transmissions, drive shafts, belt + slices, brakes, screw Jacks

- Pipework systems

- Fittings

- Control valves, actuators

- Control valves, actuators

- Sealing

- Rotary joints / rotating unions or rotating joints

- Rotary joints / rotating unions or rotating joints

- Linear technology

- Functional assemblies including drawing parts, purchased and assembly parts, linear units

- Functional assemblies including drawing parts, purchased and assembly parts, linear units

- Process air components:

- Fans, compressors, blowers, air heaters, heat exchangers, filters

To apply as a supplier, please click on the button below and fill in the following application form.

Drawing parts

The basic structure of a film-stretching system consists of components which are manufactured on the basis of drawings and technical specifications. We are looking for reliable partners who can supply us with required components on time and in the specified quality.

Portfolio:

- Machining:

- Cubic and rotationally symmetrical components

- Batch size 1 max. 1000

- Incl. surface treatment (e.g nickel plating or painting)

- Incl. heat treatment

- Steel components with mechanical processing:

- Cubic components with a unit weight up to 8 t

- Batch size 1 max. 50

- Incl. painting

- Sheet metal parts:

- Laser catted parts incl. bending up to thickness of 10 mm

- Materials: steel, stainless steel, FAL and galvanized sheet metal

- Welding methods: MIG, MAG and TIG

- Sheet metal part assemblies

- Gearing:

- Component size up to a diameter of 2500 mm

- Material: steel

- Heat treatment

- Grinding

- Molding:

- Sand castings with a unit weight of up to 2500 kg

- Dimensions up to 2000 mm

- Material: GG / GGG / cast steel

- Batch size 5 max 100

- Incl. machining

- Assemblies:

- Functional assemblies, including drawing parts, purchased parts and assembly

- Functional assemblies, including drawing parts, purchased parts and assembly

- Air conditioning technology:

- Construction and production of assemblies for air conditioning process, based on technical boundary condition

- Construction and production of assemblies for air conditioning process, based on technical boundary condition

To apply as a supplier, please click on the button below and fill in the following application form.