Our commitment to high-quality suppliers: the key to success

21 Feb 2024

Customers are demanding increasingly flexible solutions for the production of polymer and fiber products. At Kiefel, we understand the importance of innovation in automation and digitalization to meet these needs and therefore, besides offering our own solutions, we rely on strong partners and suppliers to deliver exceptional results.

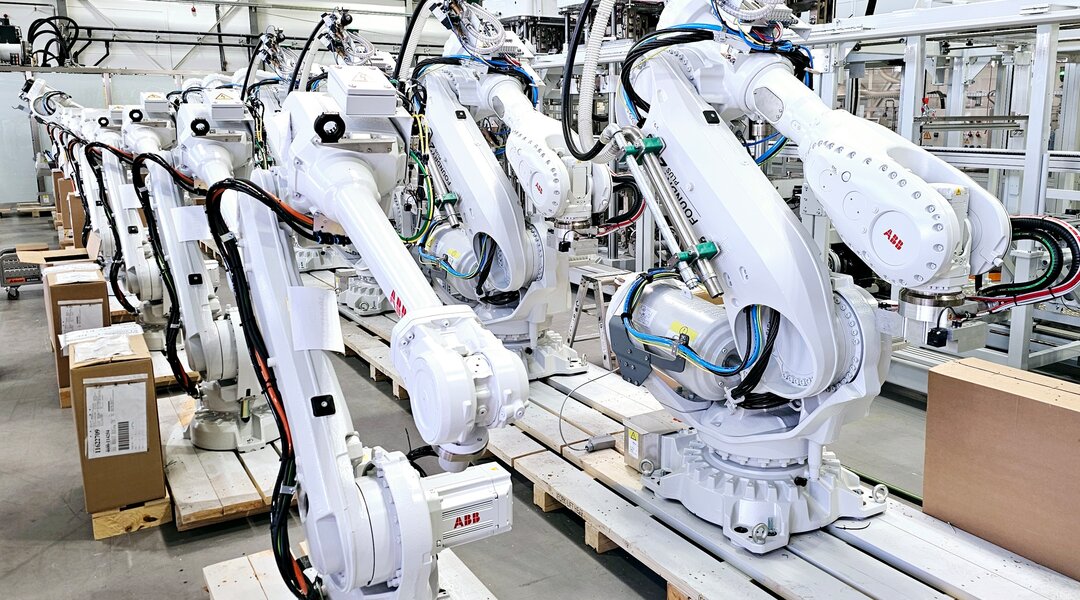

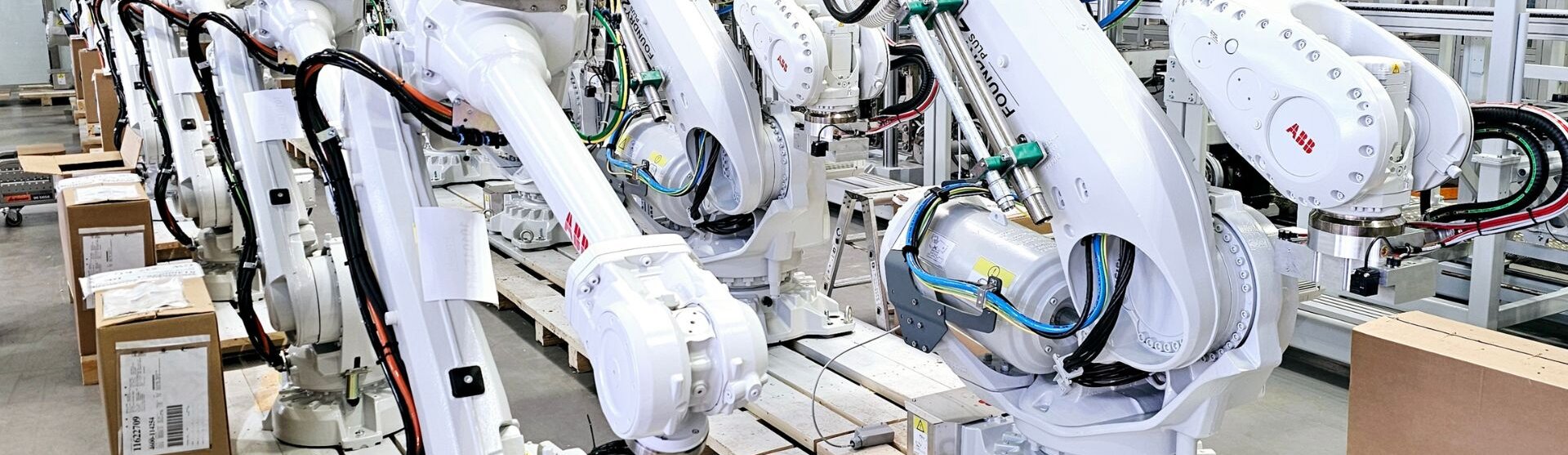

Celebrating long-term partnership: 1000+ ABB robots installed in Kiefel machines worldwide

We continuously invest in research and development of cutting-edge technology as well as in high-quality suppliers’ systems for seamless integration, providing our customers more efficient and flexible equipment.

"That is why, Kiefel has proudly worked for over two decades in partnership with ABB, a pioneering supplier in robotics and machine automation, to successfully stay at the forefront of machine technology in different sectors of our operations," explains Martin Ploessl, Head of Procurement Components at Kiefel.

"This year, we are celebrating ABB Robotics 50th anniversary and now, we can add another highlight with more than 1,000 robots sold to our customer Kiefel”, celebrates Gabi Guter-Johansen, Head of the regional Business Line Industries, Robotics Division, ABB AG. “We are proud that our robotic solutions have been an integral part of Kiefel's innovations for many years - helping to make packaging even more sustainable".

For example, ABB robot technology for pick & place applications and for product handling tools are integrated into our KFT 90. “In the forming station, ABB robot IRB 6700 submerges the mold in the pulp basin and moves it to the pre-press station, before transferring the parts to the next station”, explains Richard Hagenauer, Head of Product Management in the Fiber Division at Kiefel. “If necessary, an additional robot can be deployed at the trimming station for efficient parts transfer”.

Furthermore, ABB MultiMove Technology allows up to four employed robots to run on one controller. Even liquids, high temperatures and harsh environmental conditions are no problems for the Foundry version of the robots.

Moreover, ABB's commitment to digitalization plays a crucial role in enhancing production efficiency. We test and refine robot installations in a virtual environment in ABB’s software RobotStudio®, where collision-free movement, cycle times and much more can be simulated and validated, resulting in faster commissioning.

"When our in-depth robotics expertise meets Kiefel's innovative strength and application expertise, this results in solutions that offer customers added quality, efficiency and sustainability. Kiefel is a multi-award-winning ABB value provider and we look forward to shaping the future together", highlights Sebastian Spanfelner, Manager Sales - General Industry Germany, Robotics Division, ABB AG.