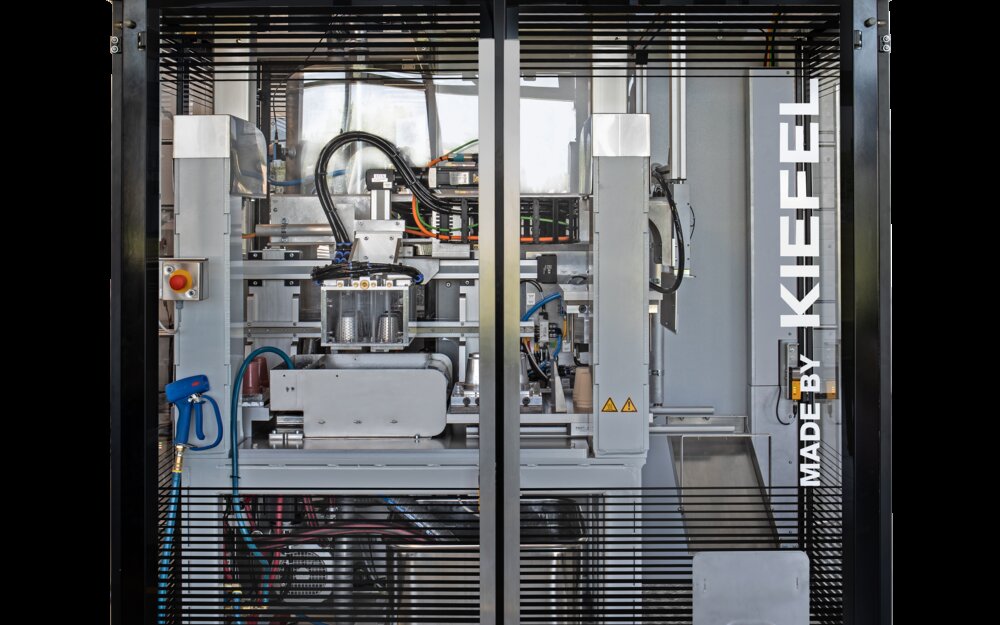

Machine solutions for natural fiber - NATUREFORMER KFT

The NATUREFORMER KFT 90 includes a range of innovative features that will increase the productivity.

With improved steam management, the Kiefel Steam Flow Technology enables a remarkable 30% reduction in cycle time - meaning faster production and greater efficiency than before. In addition, its new temperature controller ensures the highest process reliability possible, offering full control over every aspect of the operation. With an optimized HMI interface simplifying machine operation, it's easier to get started on producing high-quality parts right away without any losses or delays. Furthermore, due to its advanced molding processes which reduce weight variation while increasing acceptable part amounts simultaneously – customers can expect higher gains.

Distinct Kiefel production process

The key feature of our machines is the thermoforming process itself: The water extraction procedure in combination with the cold pre-pressing technology reduces the moisture up to 60 %

The final press with heated tools reduces the residual moisture of the packaging product to approximately 7%.

Why NATUREFORMER KFT?

Top product quality

Very high molding accuracy due to type 3 fiber molding process

Everything from one single source

From fiber preparation to automation | Machine concept with integrated pulp basin, inline trimming station and end product packaging solutions

Energy efficient production

Thanks to the seperate pre-press station, only one station is needed for hot pressing. This saves energy and maintains the highest quality at the same time.

Proven Kiefel modules

Proven and reliable toggle concept with servo drives and years of success in the market

High degree automation

Stacking, sleeving, boxing, palletizing, automatic inspection, etc.

Versions of the NATUREFORMER KFT

| KFT Lab | KFT 90.1 | KFT 90.1 incl. trimming / die cut | |

|---|---|---|---|

| Max. forming area | 300 x 200 mm | 900 x 700 mm | 900 x 700 mm |

| Height of formed part | max. 130 mm | 120 mm | 120 mm |

| Pressing force | 26 kN | 450 kN | 450 kN |

| Formed weight per cycle* | 350 g | 350 g | |

| Footprint | 3.7 x 3.1 m | 10.6 x 4.1 x 3.9 m | 12.3 x 4.6 3.9 m |

*referred to our reference product

Compact and perfect solution for research & development

The KFT Lab is the solution for research and development as well as for the production of molded fiber samples for product development. The Lab machine's small footprint and compact size, as well as manual and automatic processing, make it the perfect choice not only for start-ups, but also for experienced manufacturers to optimize their production process.

New generation fiber thermoforming technology for higher output

Thanks to its over 15% larger forming area and its advanced technology, the cutting-edge NATUREFOMER KFT 90.1 enables you to achieve a higher output of a wide variety of fiber packaging, such as lids, coffee capsules, bowls, cups, and flowerpots.

Tool change has also been optimized with lighter suction tooling and a new forming tool design as well as a larger space for tool change on non-operating side, making the process easier and faster.

The new KFT 90.1 standard solution for high-quality fiber packaging production also features up to 10kW lower energy consumption or up to 900L/h less water consumption for machine operation.

Kiefel Driving Digital – KMI 2.0

Intuitive machine operation

Dive into the world of thermoforming 2.0 with the new machine interface generation KMI 2.0! The intuitive machine operation simplifies your thermoforming processes and supports you in many ways:

- short training time

- fast recipe optimization

- fast error handling

- guided maintenance system