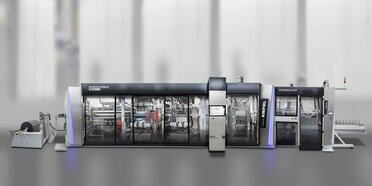

Upstream & Downstream solutions

for your thermoforming machines

Here you will find the right solution for upstream and downstream processes around your thermoforming machine. At the beginning of the thermoforming process, an unreeling unit is required for the film rolls, after which the film is heated by a preheater.

Downstream, film residues can be grinded by a skeleton grinder and thus prepared for the new feed into the thermoforming process.

Learn more about our upstream/downstream solutions below.

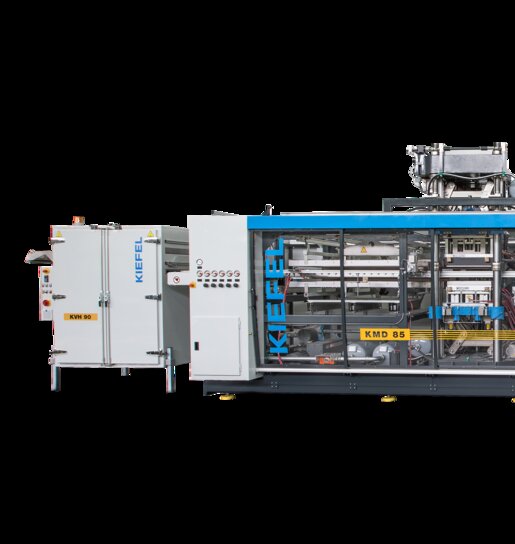

Unreeling Unit KA

The KA unwinding unit enables sophisticated control of film rolls --> no stop & go.

It indicates the end of the film and can be modularly extended by a lifting device and ultrasonic joining unit.

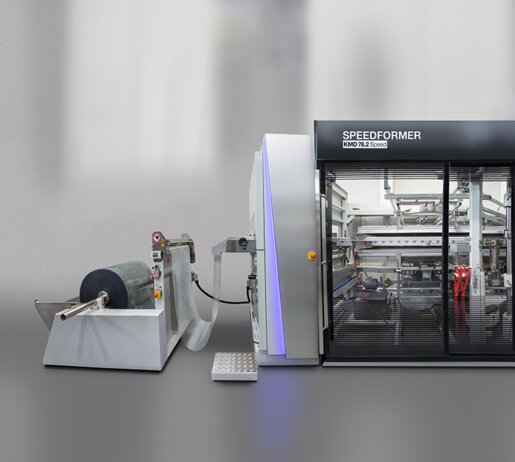

Preheating KVH

The preheater KVH has a sophisticated control of the film loops -> no stop & go.

Due to the efficient film heating, the power consumption can be kept low. The KVH can also score as an independent unit with non-Kiefel machines.

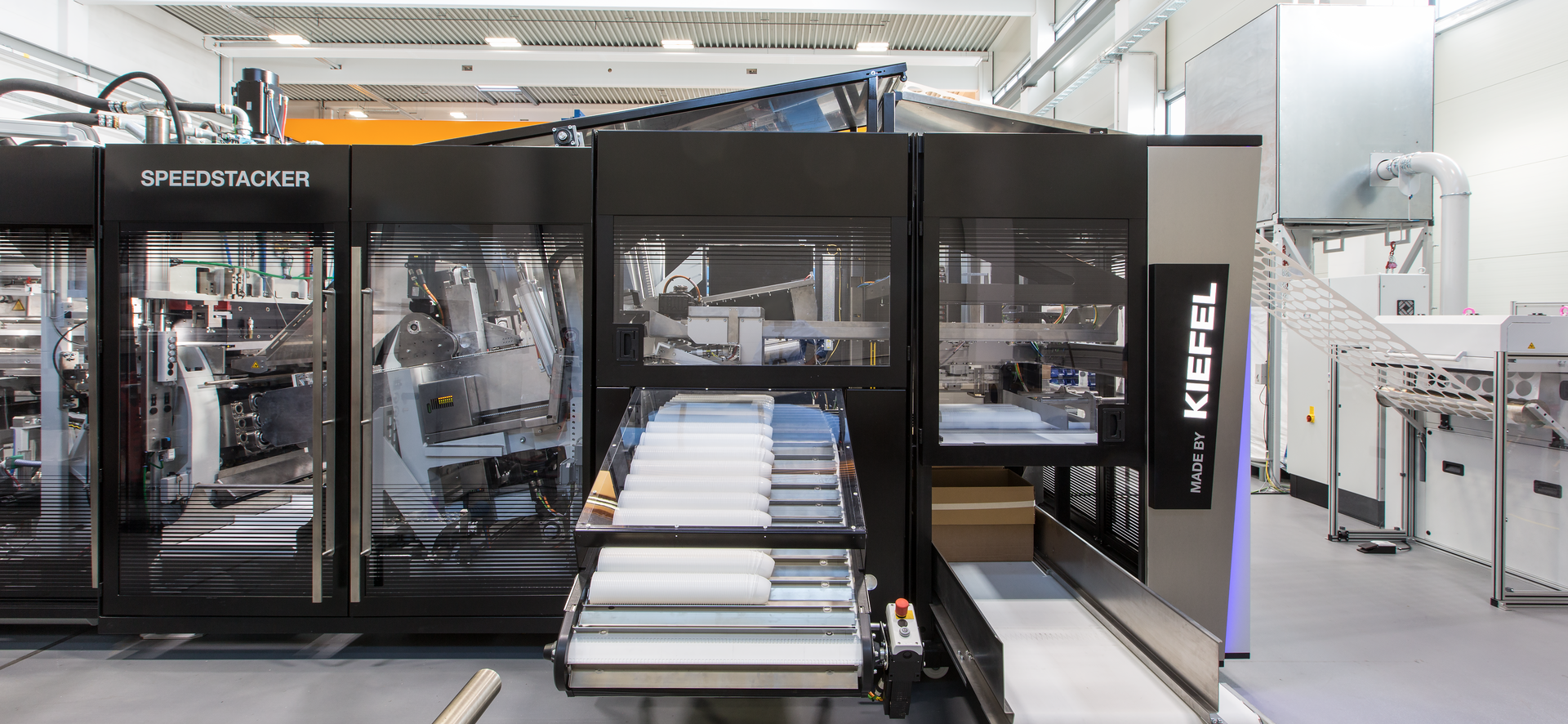

SPEEDGRINDER (KSG)

The SPEEDGRINDER is a so-called "skeleton grinder" which grinds the residual skeleton which is produced in the thermoforming process after the packaging has been cut out. The crushed smallest parts can then be fed back into the extrusion process and thus be processed into plastic film again.

The KSG - available in two versions - is characterized by high operational reliability and maximum machine utilization. The generously sized access doors offer a significant advantage during maintenance. Designed to meet the highest requirements of food and safety regulations, the KSG stands for grinding solutions with the lowest noise and dust levels in the industry.

Benefits:

- Low dust and noise levels due to low rotor speed and the excellent sound insulation, significant noise reduction due to insulation of the granulator unit from the undercarriage.

- Grinding of the highest quality due to optimum feed speed and rotor cutting speed for best material quality (prevents long parts - specks); suitable for any application thanks to three rotary knives, a generously designed grinding chamber and a powerful motor

- Good accessibility for maintenance and cleaning due to milled and bolted grinder housing on wheels with pull-out screen

- Closed-loop recycling management - residual grid is directly reused, thus waste is avoided

Technical Highlights:

|

KSG 90-400 - |

|

|

KSG 90-600 - |

|

| Motor power | 22 kW (Max.) |

| Infeed opening | 920 mm |

| Max. noise level | 80 dB (real production) |

| Rotor speed | 420 rpm |