BOPP and BOPE Inline Coating: Perfect barrier, improved recyclability

15 Dec 2020

Brückner’s solutions for new and used equipment

Driven by the discussions about recycling targets for plastic packaging, mono-material packaging structures are receiving more and more interest: for example, biaxially oriented polypropylene (BOPP) or polyethylene (BOPE) films. Reasons for this are a better sortability of the packaging and an improved quality of recycling materials. With mono-material structures the question of barrier solutions and their role for recycling comes up. If one looks at traditionally used aluminum metallized films or aluminum foil, future packaging designs demand a transparent barrier solution like AlOx, SiOx or EVOH.

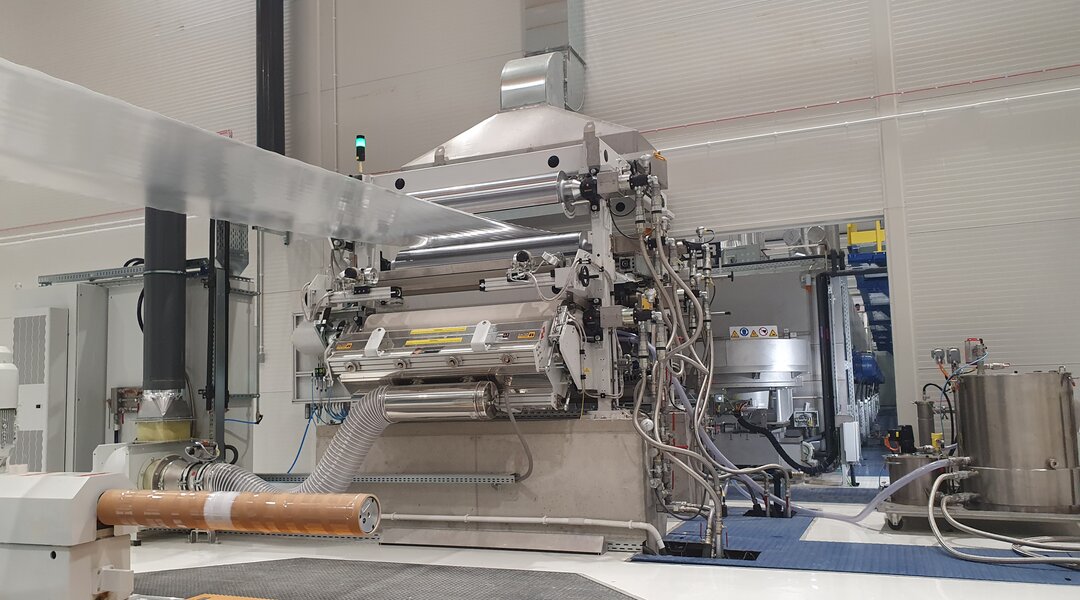

Here the inline coating technology offers decisive advantages for BOPP and BOPE applications. Brückner’s newly developed technology is installed between the machine film orientation (MDO) and the transverse film orientation (TDO) process: A wet chemical treatment applied there directly inline provides a tailored base-layer (primer) for the subsequent AlOx / SiOx metallizing step and can be used at regular 3-layer BOPP or BOPE film stretching lines.

The metallization layer is a perfectly bonded, very homogeneously distributed over the complete film width and shows outstanding oxygen and water vapor barrier values – comparable even to high-barrier films such as metallized BOPET or aluminum foil. Since the coating material is water-based, transparent and in nanometer scale (typically < 100nm), the environmental impact and effect to the recyclability is minor and thus within the strict laws and regulations. It is even superior from an economical point of view to any barrier solution with EVOH. Besides this, the treatment is long-term stable without decay.

Benefits of inline coating at one glance

- Huge variety of possible applications and film types

- Cost efficiency

- Thinnest, very consistent coating layers in the nanometer scale

(< 100 nm): Low coating material costs - No additional corona treatment needed on coated surface

- Low investment costs due to the narrow coating width before transverse orientation

- Utilization of the transverse orientation unit’s pre-heating zone as dryer: energy optimized process without separate dryer

- Low operation costs by saving expensive off-line coating processing steps

- Thinnest, very consistent coating layers in the nanometer scale

- Enhanced film properties

- Improved bonding of the coating to the film in the virgin, not yet crystalline state – superior to offline-coating

- Improved printability

- Significantly higher metal adhesion – perfect barrier improvement after metallization

(Al / AlOx / SiOx) - Antifog and antistatic layers

- Long term stable surface energy

- Improved recyclability due to lowest impact of the thin layer technology

The inline coating technology is not only available with new Brückner film stretching lines but can also be upgraded on used lines. Brückner Servtec has a complete concept for the line modification:

- Tailored upgrade package for existing BOPP film-production lines

- Full integration in the existing control system

- All necessary modifications of existing components to run inline coated film

Film producers going that upgrading step profit from Brückner Servtec’s know-how of coating formulations and process, the experience of more than 40 installed Brückner inline coaters for BOPET and BOPP, the comprehensive R&D resources at the Brückner headquarters as well as a network of corresponding partners in the industry.