Trend in composite current collector film production: Efficiency up, thickness and costs down

07 Nov 2024

Brückner’s LISIM® technology is the first choice when demands increase

Lithium-ion batteries are the state-of-the-art power source for multiple applications, ranging from consumer electronics to electro mobility. Current collectors are an indispensable part that bridges lithium-ion batteries and external circuits, greatly influencing the capacity, rate capability and long-term stability of lithium-ion batteries. Conventional current collectors work with full metal (aluminum and copper) foils and have been in use since the first commercial lithium-ion battery.

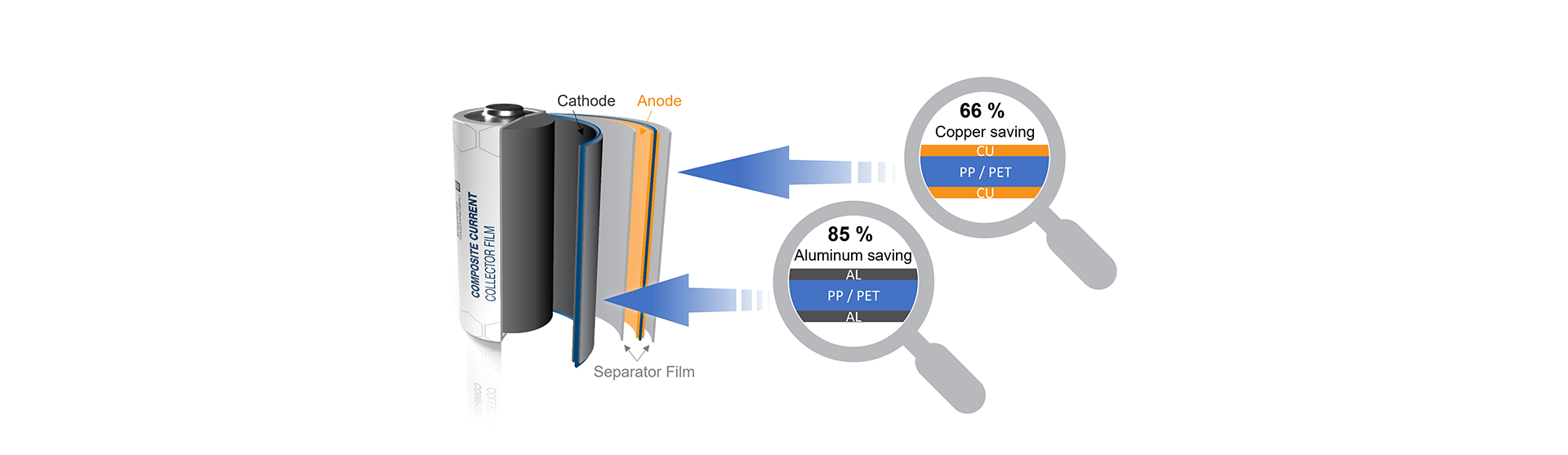

However, in order to reduce weight, enhance energy density, and reduce costs, alternative materials such as composite current collector plastic films are needed for next-generation lithium-ion batteries providing a higher capacity and longer service life. And very, very important: also providing higher safety: if damaged, e.g. by nail penetration, the composite current collector prevents the resulting thermal runaway of the battery. A current example are new battery safety regulations introduced in China, favoring composite current collector – they are meanwhile accepted by the industry. This should boost aluminum/copper plated polymer films (metal layer thickness 1 µm) made of PP or PET as replacement of pure aluminum/copper foil in batteries.

Most certainly, the biaxial stretching technology has proven to be the best when it comes to composite current collector base film production. No matter whether a film manufacturer wants to use the sequential or simultaneous stretching process – Brückner Maschinenbau offers both proven technologies. Leading Asian film manufacturers with the appropriate know-how in the downstream processes have already ordered Brückner lines – both, sequential as well as simultaneous ones.

The trend clearly noticeable in the market is to make current collectors lighter and thinner and thereby increasing the energy density of power batteries, due to ultra-thin composite current collectors. And this is where Brückner's simultaneous LISIM® technology comes into play. Today, the typical film thickness for polymer composite current collector base film is 4.5 µm, thicknesses below this number can already be found on the market and further down-gauging is expected even to less than 2µm for the base film. The LISIM® technology has clear advantages with ultra-thin film production while tuning the mechanical properties to their limits at the same time.

In addition to the trend towards ever thinner films, other topics are also on the agenda of Brückner’s Technology Center in Siegsdorf: measures to optimize the downstream process for widening up the operation windows towards higher speeds and wider working widths resulting in a more cost-efficient production is a major target for our ongoing development process.